class 100 clean room iso equivalent

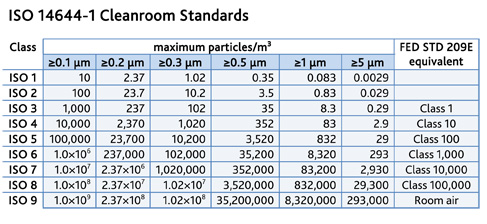

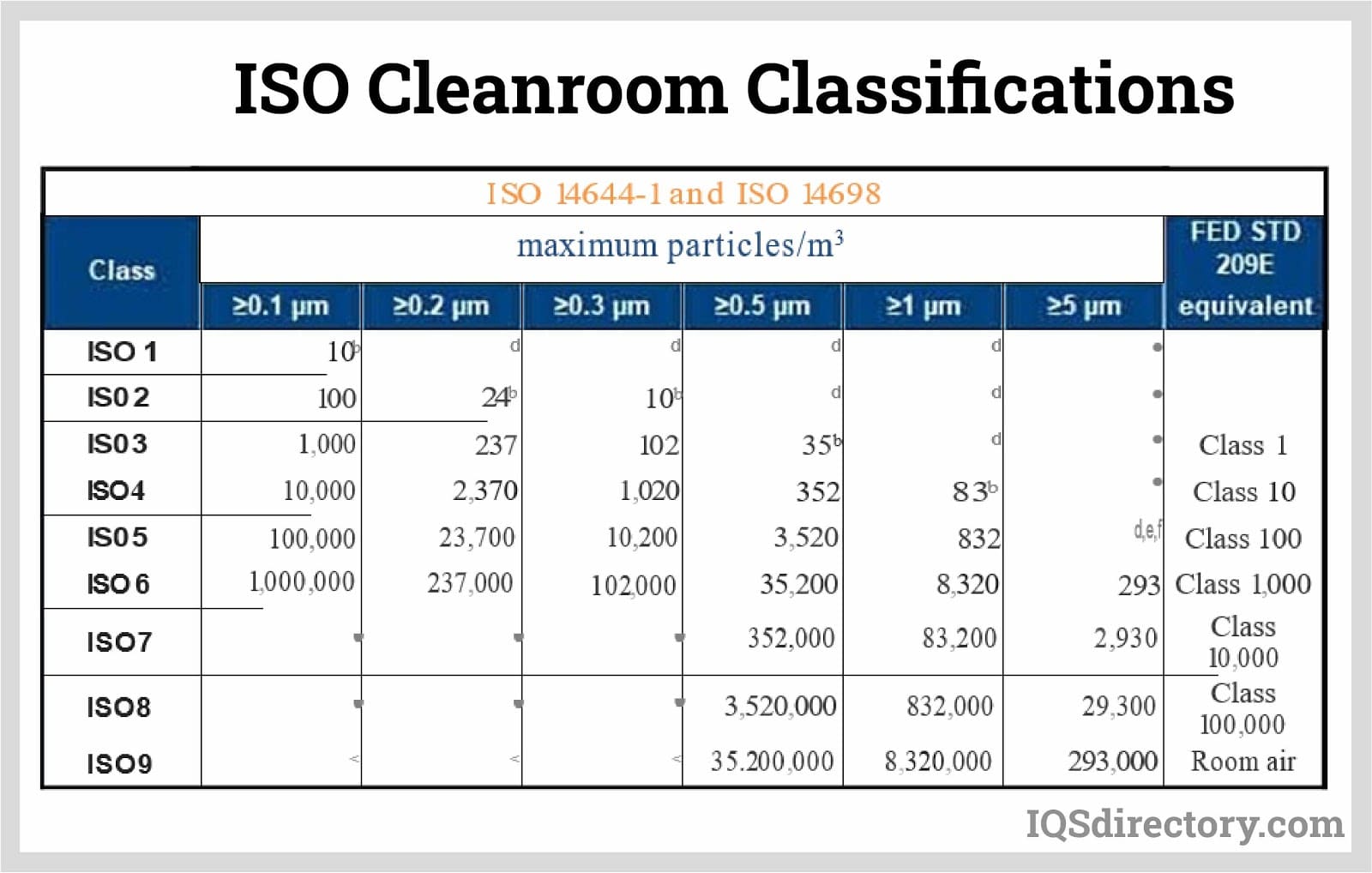

Therefore a class 100 cleanroom is particularly designed to allow not more than 100 particles per cubic foot of air. For example ISO 5 cleanrooms will require around 250-350 unidirectional airflow changes per hour to maintain its ISO grade.

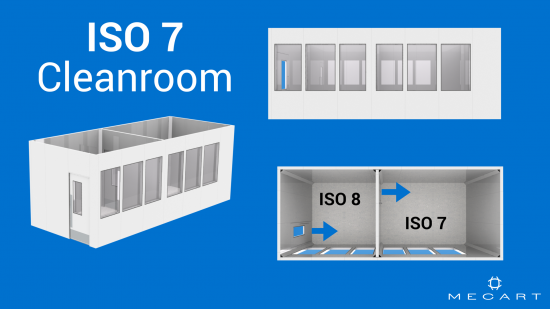

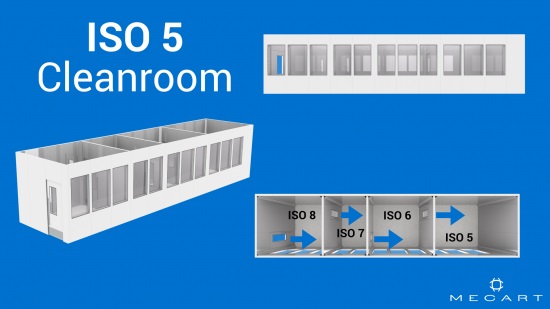

Understanding Cleanroom Classifications Iso 8 Iso 7 Iso 6 Iso 5

To meet the same standard using the high-end air change recommendation 480hour.

. Ad Over 20 Years As A Leading Manufacturer Of Cleanroom Supplies Wiping Solutions. These tables detail the air changes and particle counts that define each class. Cleanroom laundered individually inspected and double packaged in cleanroom bags.

Human air measures about 75 to 100 microns in diameter and a particle. To meet the same standard using the high-end air change recommendation 480hour. Read About How We Build Cleanrooms Comparison of Cleanroom Classifications For cleanrooms and clean zones.

The classification of these tolerances is done in line with the International Standards Organization ISO guidelines. Even though ISO 9 cleanroom environments are classified as the least clean theyre still cleaner than a regular room as a standard office space likely contains more than 1 million particles per cubic meter. The use of pre-saturated wipes with a blend of 70 Isopropyl alcohol and 30 Di Ionized water is very effective when.

Low in non-volatile residue and ionic levels. Both layers are heat-bonded together and the edges are laser cut and sealed making this wipe one of the cleanest available on the market. ISO 14644-12015 Cleanroom Classification.

Class 100 Cleanroom is the third classification type of the FED-STD-209 classification standard the Class 100 Cleanroom corresponds to the Class 5 Cleanroom of the ISO standard. Class 5 Cleanrooms for Micropropagation Cell Culture. As one example a 2015 study demonstrated an improvement in embryo quality and clinical pregnancy rate after a facility upgraded their cleanroom from a class 1000 ISO 6 to a class 100 ISO 5.

Of volume requires 6 FFUs. The required level of cleanliness for a Grade A area is obtained using a laminar flow cabinet or a laminar airflow hood LAF. Leading Manufacturer of Cleanroom Supplies Contamination Control Products.

Meeting Class 100 standards using the low-end air change recommendation 240hour inside a 12 x 12 x 7 3302 mm x 3302 mm x 2134 mm cleanroom with 1008 cu. However class will greatly impact design considerations such as filtration HVAC requirements and other design elements. Up to 4 cash back class 10ISO 4 cleanroom but also can be used in a class 100ISO 5 cleanroom.

ISO 1 is the cleanest class of cleanroom while ISO 9 is the least clean. This means that whether employees are working or not the cleanliness inside the cleanroom must maintain Grade A levels ISO 5. Discover the different classes within the cleanroom ISO standards and their Federal Standard and GMP equivalent.

For example an ISO Class 8 cleanroom requires a minimum of 10 air changes per hourthe air inside the. Once a cleanroom has been built then it should be maintained according to those original standards in order for it to attain peak performance. ISO 14644-1 and older standard FS 209E determine class by the concentration levels of particles.

300 per cubic foot. Our ISO 5 Class 100 Cleanroom Wipes offer the following features and benefits. However there are basic requirements that every cleanroom should meet.

100 per cubic. Of volume requires 6 FFUs. HEPA filter coverage required is 5-15 of the area.

ISO 5 cleanroom has less than 3520 particles 05 microns per cubic meter and 250-300 HEPA filtered air changes per hour. The equivalent Federal standard is class 100 ISO 6 cleanroom specification is quite similar to ISO 5 but it has 180 HEPA filtered air change per hour basis. Class 100 000 cleanroom has a maximum particle count of 100 000 particles per cubic foot in air corresponding to an ISO 8 cleanroom which is at the low level of cleanroom standards.

A cGMP Grade A environment is equivalent to an ISO 5 for both at rest and in operation. Meeting Class 100 standards using the low-end air change recommendation 240hour inside a 12 x 12 x 7 3302 mm x 3302 mm x 2134 mm cleanroom with 1008 cu. The particles range in size from 1 -5 microns µm.

Cleanrooms By United provides ISO Class 5 Class 100 through ISO Class 9 ambient cleanrooms. Continuous polyester fibers help prevent particle emissions. The maximum allowable particles for particles for a Class 100 Cleanroom are below.

The class defines a minimum cleanliness level not a specific design. To find this divide the volume of the room by the volume of air filtered in an hour the resulting figure is another important factor in determining a cleanrooms ISO classification. However there are basic requirements that every cleanroom should meet.

FED STD 209E equivalent 01 um 02 um 03 um 05 um 1 um 5 um. 750 per cubic foot. The equivalent federal standard is class 1000.

Clean Room Classifications Iso Standards Quotes 48 Hours

What Is A Cleanroom Cleanroom Classifications Class 1 10 100 1 000 10 000 100 000 Iso Standard 14644 Cleanroom Definition

Understanding Cleanroom Classifications Iso 8 Iso 7 Iso 6 Iso 5

Clean Room Classifications Iso Standards Quotes 48 Hours

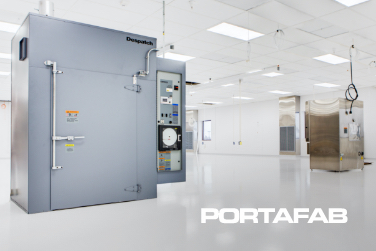

Portafab What Is A Clean Room Cleanroom Design Classification

Cleanroom What Is It Iso Standards And Classifications Design Types Construction

Fed Std 209e Class 100 Cleanrooms Iso Class 5 Clean Rooms

Cleanroom Classifications Explained

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classifications Iso 8 Iso 7 Iso 6 Iso 5 Mecart

Understanding Cleanrooms Particle Count Hutchins Hutchins

Clean Room Classifications Iso Standards Quotes 48 Hours

Ach Cleanroom Iso Standards Ach Engineering

Cleanroom Classification Classes And Standards Portafab

Iso 14644 1 Cleanroom Standards Download Scientific Diagram